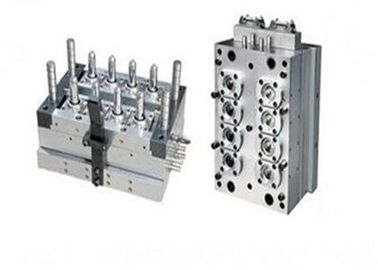

Custom Made Plastic Injection Mold For Automobile Parts / Electronic

Quick Detail :

Model NO : DW-mould14

Place of Origin : Guandong China(Mainland)

Mould Runner : Cold / hot or Yudo Runner

Shaping Mode : Injection Mould

Mould Cavity : Single Cavity, Multi Cavity

Installation : Fixed

Export Markets : Global

Detailed Product Description :

Part Material : PE , PVC ABS , PC , PP , POM , PA6 ( PA66 , Gf Filled ) , P

Mould Steel : P20 , H13 , 718h , Nak80 , S136 , 2311 , 2344 , 8407

Design & Program Soft Wares : CAD / Cam / Cae , Ug , Proe , Powemill , Solid Works etc

Plasitc Mould Gate : Sprue / Side / Sub / Winkle / Hot Runner

Plasitc Mould : Supply All Kinds Custom Mould

Plasitc Mould Base : LKM , DME , HASCO , FUTABA , MISUMI , PUNCH etc

Application : Car , Household Appliances , Furniture , Commodity , Electronic , Home Use , Hardware

Application :

We are always committed to close cooperate with large mould and parts manufacturers around the world with years of experience , high production standard and a good reputation in mould manufacturing field . The leading moulds and parts include : automotive accessories , household appliances , consumer electronics , office automation , health care and medical instruments , etc

Specification :

|

Place of Origin :

|

Shenzhen , China ( Mainland )

|

|

Brand Name :

|

DWTC

|

|

Shaping Mold :

|

Plastic Injection Mould

|

|

Mold Steel :

|

S50C , P20H , 718H , SKD61 , S136 , NAK80 , 8407 , 2344 , 2767 , etc

|

|

Quality Certificate :

|

GB/T 19001-2008 / ISO 9001: 2008

|

|

Cavity :

|

Single or Multi

|

|

Runner :

|

Cold or Hot

|

|

Drawing files :

|

PROE / UG / AutoCAD / Solidwork etc

|

|

Part Material :

|

PP, ABS, PC, PE , Nylon , tpe , pomm , etc

|

|

Surface Treatment :

|

Texture , Polish , etc

|

|

Facilities :

|

CNC , Grinding , Milling , Lathe , EDM , Drilling , etc

|

|

Mould Base :

|

LKM / DME / HASCO / FUTABA , etc

|

|

Mold life :

|

At List 1 , 000 , 000 Shots

|

|

Packaging Details :

|

Wooden pacing or according to customers ' requirements

|

|

Applications :

|

Electronics , Packaging , Industrial , Automobile , Sports , Household , etc

|

Competitive Advantage :

1. HASCO,DME ,LKM ,FUTABA,PUNCH, MISUMI Standard etc.

2. Multi-cavity Mould, Over Moulding, Gas-assisted, Hot Runner Moulds, Double-coloured mould

3. Tooling Lead Time is as Short as Possible

4. Best Quality at a Reasonable Price

5. Always have 1 contact person during the whole project for both mold and molding. Every week update

the working process to clients.

6. Be on your service 24 hours , and make a specific quotation for you within a day.

We offer :

Mold engineering show :

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!