fully automatic hot runner system injection molding machine HM-270 for hangers

ADJUSTMENT UNIT:

Automatic mold height adjustment save time and cost during the mould change

CLAMPING UNIT:

The plates are designed using FEM software,ensuring a stable and rigid clamping system.

Five point inward moving double toggle system ensures high rigidity and precision for mould clamping and also reducing stress and strain effect

HYDRAULIC UNIT:

The hydraulic system using the world famous pump and control valve can control the machine running precisely, ensuring the precision, reliability and durability of whole machine

INJECTION UNIT

Dual-pillar supporting and dual cylinder injection balance devices ensure the stress on screw balanced during injection

Special screw and barrel designs are available for processing different material requirements

ELECTRONICALLY CONTROLLED UNIT

CPU controller and the display are independent and reliable

A large color lcd screen enhances clear display and supports multi-language compatibility

The control system also supports remote monitor ,in the event of a control problem ,the machine can be connected to the internet through a special interface.(optional)

A screen saver function extends the LC life

Ultra brighter led is provided for input and output point inspection.

Providing convenient indication of the machine’s operation and machine service

A data hardware lock is provided to prevent unauthorized people from modifying the molding parameter and effecting the machines performance

Close loop PID barrel temperature control

Dust and waterproof control cabinent provide a near and tiny enclosure all electrical control components

Specification:

| |

HM-270 |

| INJECTION UNIT |

UNIT |

A |

B |

C

|

| SCREW DIAMETER |

mm |

55 |

60 |

65 |

| SCREW L/D RETIO |

L/D |

22.9 |

20.9 |

19.3 |

| INJECTION VOLUME |

cm3 |

594 |

707 |

829 |

| INJECTION WEIHGT |

g |

540 |

643 |

755 |

| oz |

19.06 |

22.68 |

26.62 |

| INJECTION RATE |

cm3/ s |

213.4 |

254 |

298 |

| INJECTION PRESSURE |

Mpa |

200 |

168 |

143 |

| CREW SPEED |

rpm |

160 |

| CLAMPING UNIT |

|

|

| CLAMPING FORCE |

kN |

2700 |

| MOLD OPEN STROKE |

mm |

550 |

| SPACE BETWEEN TIE BARS |

mm |

580×580 |

| MAX.MOLD HEIGHT |

mm |

200~550 |

| EJECTOR STROKE |

mm |

150 |

| EJECTOR FORCE |

kN |

70 |

| OTHERS |

|

|

| MAX.PUMP PRESSURE |

Mpa |

16 |

| PUMP MOTOR POWER |

kW |

22 |

| HEATER POWER |

kW |

16 |

| MACHINE DIMENSIONS |

mm |

6×1.5×2.2 |

| OIL TANK CAPACITY |

L |

365 |

| MACHINE WEIGHT |

t |

8.3 |

Advantage:

1. T Slot Platen;

2. Machine Weight more than most factory.

3. Machine base use rectangular Tube.

4. 4pcs safe door are moveable,maintain the machine more easy;

5. Hydraulic tank is moveable,more easy to clean the tank,

6. heating band is made by cermics,use life is long

7. prepare more spare parts for customer

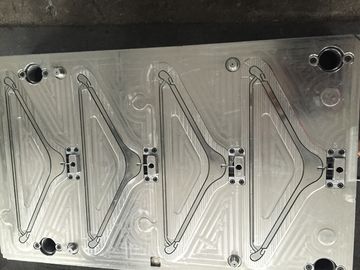

Platen drawing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!